Visual inspection of an original tape may reveal physical and chemical problems that will need to be dealt with to preserve the tape and to capture the best-possible signal from it. The physical and chemical problems may even lead to serious damage during replay.

HOW:

First analysis of general condition after opening the box: Smell the tape to see if it smells of vinegar (but only with tapes not showing signs of mould - health risk!). Vinegar smell is caused by acetic acid that is given off due to a decay process commonly called the Vinegar Syndrome.

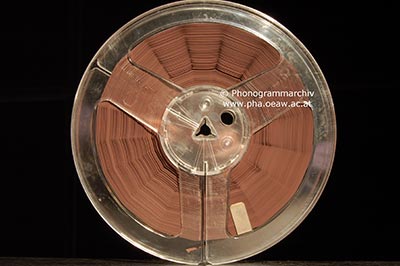

Inspect the tape visually for any mechanical or physical damage:

- 1.1.1. Look for pack problems

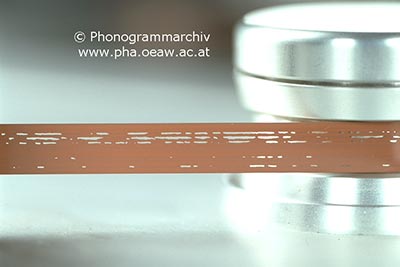

- 1.1.2. Look for chemical deterioration /

Vinegar syndrome

- 1.1.3. Look for chemical deterioration / Binder

degraration

Attention: Do not rewind or even play precarious tapes! The result may be total breakdown.

SEE:

Specs Bros: Basic Inspection Techniques to Sample the Condition of Magnetic Tape

Capturing Analog Sound for Digital Preservation: Report of a Roundtable Discussion of Best Practices for Transferring Analog Discs and Tape

National Media Laboratory: Magnetic Tape Storage and Handling

Richard L. Hess: Winding tapes for long-term storage

Gerald D Gibson: Magnetic tape deterioration: recognition, recovery and prevention

AHDS: Creating Digital Audio Resources. A Guide to Good Practice

Chemical winding problem

Acetate deformation

Oxide shedding

Tape breakdown